The Commodity Side of Hardwood Flooring…What Really Determines the Price of Oak Flooring?

There is definitely a positive upward trend in residential home building. After years of weak demand for new construction, builders in most regions of the country are finally seeing more activity, bidding more work and signing more contracts. A critical consideration in this trend is therising cost of lumber, perhaps the single biggest cost factor in new home construction. Dimensional lumber, like most commodities, has fallen victim to the inflexibilities of supply and demand. Exacerbating matters is five years of downward commodity pricing pressures matched alongside brutal competitive pricing. Now it appears all hell is breaking loose.

There is definitely a positive upward trend in residential home building. After years of weak demand for new construction, builders in most regions of the country are finally seeing more activity, bidding more work and signing more contracts. A critical consideration in this trend is therising cost of lumber, perhaps the single biggest cost factor in new home construction. Dimensional lumber, like most commodities, has fallen victim to the inflexibilities of supply and demand. Exacerbating matters is five years of downward commodity pricing pressures matched alongside brutal competitive pricing. Now it appears all hell is breaking loose.

The same can be said for hardwood flooring. As of this writing, most sources report flooring oak lumber prices have increased a whopping 40% since the end of 2012. And unfinished strip and plank flooring is a prime example of a pure commodity product. So manufacturers have been forced to raise prices at a rapid pace. The Hardwood Market Report(www.hmr.com) has been publishing prices weekly since 1922. Hardwood flooring prices have always dropped in times of recession, and increased robustly in times of market growth. But excluding the Great Depression, the last three generations in this country have not witnessed such a prolonged depressed market. Having created enormous pent-up demand, we are again sailing in uncharted inflationary waters.

While it’s hard to argue differences in the features, advantages and benefits of dimensional lumber (grade for grade), a different case can be made for unfinished hardwood flooring. Sadly, there is nothing we can do about dimensional lumber and strip flooring both being commodities. But I believe you can develop product differentiation between unfinished flooring due to its regional raw material source. Marketing their respective differences can sometimes get you a leg up on the commodity price treadmill.

Oak Species (by Geographical Origin of Supply) – Red and White Oak are the most dominant commercially harvested hardwood species in North America. There are three distinct oak species, each determined by their region of supply: Northern Oak, Appalachian Oak and Southern Oak.

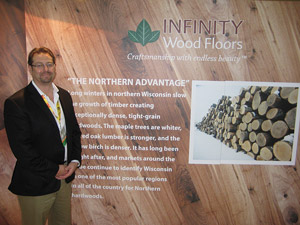

Northern Oak, in sufficient supply to be commercially harvested, grows predominantly in the states of Wisconsin, Michigan, Northern Indiana and Minnesota, as well in the eastern provinces of Canada. What makes Northern Oak different from the Appalachian or Southern species is that the colder climate conditions create a slowergrowing season. As such the growth rings in the timber are closer together and this creates a tighter, more consistent (and unique) grain pattern. For this reason, Northern Oak has been coveted by furniture manufacturers for decades.

It is usually available in less supply than oak in the other regions. Its beautiful consistent grain and shorter supply make it more costly that the Appalachian and Southern varieties. Adding to the equation is that northern oak grades-out a higher percentage of the upper grades, leaving less #2 and #3A flooring grades. The result is that while still priced as a commodity, Northern Oak hardwood flooring has always fetched a higher price. Given an opportunity to market and sell the beauty of Northern Oak, you can easily justify a price premium.

Appalachian Oak lumber grows in the mid-central U.S. region, primarily in central and southern Kentucky, southeastern Ohio, West Virginia, Tennessee (higher elevations) and western North Carolina. The mountains of Tennessee and North Carolina are especially ideal for flooring oak as the mountain growth offers a slower growing season and also creates a tighter grain pattern. This species is closer in look to Northern Oak than Southern, and is in greater supply than Northern but considerably less than Southern Oak. This results in Appalachian Oak prices being more than Southern Oak, and less than Northern.

Southern Oak– The largest stands of commercially harvested Red and White Oak timbers are located in the southeastern states of Mississippi, Alabama, North Carolina, South Carolina, Georgia and southern Tennessee. The oak forests of the Deep South are a true treasure trove of natural resources for the United States. Weather conditions in this region are ideal for faster timber growth, which leaves a wider spacing between growth rings in the timber and creates a less consistent grain pattern.

The mineral rich soils of this region create a greater natural color variation in the wood. The term “mineral streak” is just that, and certain grading rules have been established that allows for different amounts of mineral in the milled flooring product (refer to NOFMA grading standards published by the National Wood Flooring Association). Indeed, Mother Nature plays a key role in the grand scheme of oak lumber including determining comparative commodity price levels for the different regional species ofunfinished hardwood flooring.

If everyone bought only the lowest-priced commodity product in this or any industry I doubt business would be very profitable. Yes, price is important, but in this industry so are Milling Tolerances, Grading Consistency, and Quality & Service.

Milling Tolerances– Not all unfinished strip flooring mills are members of NOFMA (National Oak Flooring Manufacturers Association). Sometimes you can find a lower-priced product from a non-member mill that appears to be of good quality, and very well may be. But the main advantage of buying from a NOFMA mill is that they all produce to the same milling tolerances (for the tongue and groove, and end match), abide by the same grading rules and are subject to regular in-plant inspections. You can get a listing of NOFMA members from the National Wood Flooring Association’s website, www.NWFA.org.

Grading Consistency– Price varies by grade. So if you are willing to pay the premium for select and better grade vs. #1 common grade, you need to be sure you are getting an honest representation of what you ordered. Again, dealing with a reputable flooring manufacturer is the key to getting an honest grade and a fair quantity count per bundle, as well.

Quality and Service– These are the intangible factors. If you are a retailer, when you call your distributor to get a current price on strip or plank flooring you should always ask for the name of the flooring producer. Many dealers are just satisfied with getting the best commodity price. My advice is to ask up front the brand name of product line you are dealing with, and what you can expect quality-wise from that line. This will avoid a good number of issues after the fact, which, as you know, could get very costly to resolve.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!