Get Serious About Silica on the Jobsite

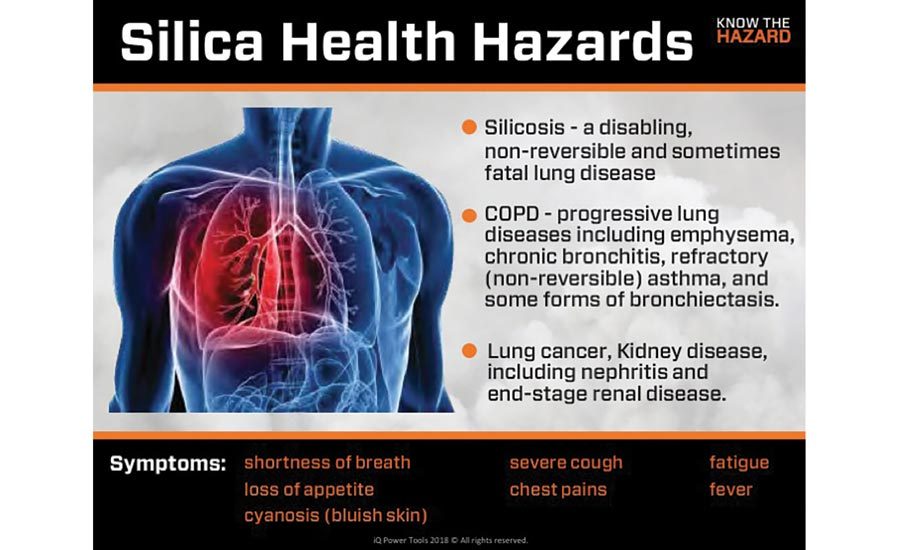

Respirable crystalline silica is a dangerous hazard that millions of workers are unknowingly exposed to every year.

Photos courtesy of iQ Power Tools

Of the estimated 2 million workers exposed, 840,000 of them are exposed to silica that exceeds the PEL or the amount of exposure deemed safe.

Every day, thousands of individuals wake up and prepare for work at the shop or on the jobsite. Many times, they are heading out to tear out and install a beautiful new tiled residential bathroom, or perhaps they are going to finish off that 2,000-square-foot luxury hotel lobby. Whatever is in store for them, aside from mixing, matching and mortaring, tile contractors need to take time to get serious about respiratory safety.

Respirable crystalline silica is a dangerous hazard that millions of workers are unknowingly exposed to every year. Of these estimated 2 million workers, 840,000 of them are exposed to silica that exceeds the permissible exposure limit (PEL) or the amount of exposure deemed safe. Around 90% of these individuals are employed in the construction industry.

The Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) have identified exposure to silica as a health hazard to workers involved in finishing and installing natural and manufactured stone products, both in fabrication shops and during on-site finishing/installation. Fortunately, this hazard can be mitigated with simple and effective dust controls in most operations1.

Professionals who are serious about OSHA compliance, site contamination and employee safety recognize the importance of enforcing strict standards relative to airborne hazards like silica or other harmful materials such as airborne asbestos. The safest of jobsites are where every employee is looking out for each other by reporting accidents, maintaining equipment and following regulations.

With the OSHA Silica Standard now in effect, silica education and awareness should be paramount to everyone’s safety plan.

5 Things to Know About Silica

Know the hazard

Crystalline silica is an extremely common mineral found in granite, sandstone, quartzite, various other rocks and sand that becomes dangerous when disturbed. Finished natural and manufactured stone products, porcelain and ceramic tile products do not pose a health hazard themselves. It is the fabrication and processing of these products generating dust that can expose one to crystalline silica (quartz). Cutting, sawing, grinding, breaking, crushing, drilling or sanding of these materials generates fine silica dust that, unless contained, will seriously contaminate the air.

Tiles are not always the only culprit on the jobsite to pose exposure. Mixing mortar and grout can create a “dusty” hazard, too. These products, generally produced using cement or sand aggregate, are also comprised of silica.

Inhalation of respirable crystalline silica can lead to respiratory diseases such as chronic obstructive pulmonary disease (COPD) or silicosis. Silicosis causes inflammatory damage in areas affected by silica, causing scar tissue to form over critical lung components.

Know the standard

The 2016 OSHA Silica Standard limits silica exposure to a PEL of 50 micrograms of respirable crystalline silica per cubic meter of air or 50 µg SiO2/m3 over an eight-hour time-weighted average (TWA). Table 1 identifies occupational exposures to silica along with work practices and specified engineering control methods to limit exposure. Employers who follow the requirements of Table 1 are not required to measure silica exposure through air monitoring and are not subject to the PEL. OSHA recognizes using tools equipped with a water delivery system that supplies a continuous stream or spray of water at the point of impact or using tools equipped with a commercially available shroud and dust collection system as the work practice control methods that safely limit silica exposure.

There are alternative exposure control methods available to give contractors more flexibility in their choice of work practices and tools. These methods do require some additional control measures to be in compliance with the OSHA Silica Standard. For alternative control methods, the following applies as explained in the OSHA Silica Standard:

- PEL: The employer shall ensure that no employee is exposed to an airborne concentration of respirable crystalline silica in excess of 50µg/m3 calculated as an eight-hour TWA.

- Exposure Assessment: The employer shall assess the exposure of each employee who is or may reasonably be expected to be exposed to respirable crystalline silica at or above the action level in accordance with either the performance option in paragraph (d)(2)(ii) or the scheduled monitoring option in paragraph (d)(2)(iii) of Table 1.

- Performance Option: The employer shall assess the eight-hour TWA exposure for each employee on the basis of any combination of air monitoring data or objective data sufficient to accurately characterize employee exposures to respirable crystalline silica.

Regulation goes beyond the PEL. The other “must-haves” for companies are:

- A competent person onsite to oversee the silica program.

- A written program.

- A training program for workers.

- Record-keeping.

Know your exposure

One way to determine silica exposure is through air monitoring. To many, this may seem like a complicated, expensive process. In actuality, it’s fairly easy once one understands what is involved.

Air monitoring equipment measures air quality in a worker’s breathing area, determining silica exposure during a specific work practice. This process uses a battery-operated vacuum attached to an operator’s shirt collar, collecting air samples right where the operator breathes.

Another way to determine silica exposure is via objective data provided by tool manufacturers. OSHA defines objective data as “information, such as air monitoring data from industry-wide surveys or calculations based on the composition of a substance, demonstrating employee exposure to respirable crystalline silica associated with a particular product or material or a specific process, task, or activity. This data must reflect workplace conditions closely resembling, or with a higher exposure potential than the processes, types of material, control methods, work practices and environmental conditions in the employer’s current operations.” When a manufacturer tests its equipment, if work practice and materials used match jobsite conditions, OSHA will allow this data to be used as objective data as part of a written silica exposure control plan.

Once you learn about exposure levels, you can decide what options are best-suited to control silica exposure on your jobsites or in your shop.

Know your material

“Check Twice, Cut Once.” The old saying doesn’t just prevent mismeasurement; it’s also a reminder to check exactly what material is being cut. For example, natural stone and quartz materials contain high amounts of the natural mineral silica. Exposure varies by stone type and silica exposure can vary depending on the silica content of a porcelain or ceramic material being used.

Controlled tests of cutting tile show that airborne emissions of crystalline silica and metals are strongly related to their concentrations in tile2. If one is not sure if a product contains crystalline silica, they should check the manufacturers Safety Data Sheet (SDS).

Know your options

No matter what tool is being used — a saw, grinder or a high-speed polisher — it’s essential to wear personal protective equipment (PPE) such as protective eyewear and ear attenuators. You should also know exactly what you’re cutting into to implement proper control methods when exposing hazardous materials.

Whether you’re sizing a piece of tile or cutting blind into a wall, you should be cautious to generate airborne contamination that could contain silica dust or even asbestos particles. Whether you’re using hand or power tools, it’s important to follow the necessary precautions to protect against any unknown airborne contamination. Remember, awareness and education ensures prevention and safety, so if you need a refresher course, take it; your lungs will be thankful.

The Natural Stone Institute (NSI) technical module, “Silicosis — An Industry Guide to Awareness and Prevention,” offers tips on controlling silica exposures in stone cutting operations. It is available to workers and employers on the NSI website. Other resources from NSI can be found at www.naturalstoneinstitute.org/silica.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!